Our profession

Value chain management:

DESIGN, PRODUCTION, DISTRIBUTION,

As a specialist manufacturer and main supplier to our customers, eco-design is at the heart of our approach. Our teams work hard every day to find the best balance between environmental and technical requirements and high energy efficiency. This means rethinking every stage, from design to production, right through to distribution : an ambitious challenge for the future.

DESIGN,

Giving meaning to innovation

Construction methods, reuse and recycling, choosing environmentally friendly materials, new regulations and so on; it is by taking these developments into account that Sepalumic gives new meaning to innovation and places the construction business of tomorrow at the heart of its strategy. Our teams of industry experts and engineers are working daily on new ways to design innovative and reliable joinery systems in keeping with the times.

INNOVATION COMMITTEE

Anticipating and studying needs with our customers to co-develop the joinery solutions of the future

INTEGRATED DESIGN OFFICE

Responding from a technical point of view to the needs expressed by the innovation committee, in accordance with environmental, legislative and technical requirements

ECO-DESIGN

The choice of materials and their recyclability enable SEPALUMIC to adopt an eco-friendly approach to the design of its products

CHOOSING SUPPLIERS

Our staff use their expertise to find the best partners and suppliers to guarantee you quality and respect for the environment

CERTIFIED TESTING LABORATORY

To test and validate the products designed by the design office with appropriate tools: approved air-permeability, water-tightness and wind-resistance test bench, endurance test, impact test, etc. Laboratory equipped with a machining centre with cutting-edge tools, focusing on manufacturers and industrialists

METHODS DEPARTMENT

Adaptation of production tools to the needs defined by the design office > interface between the design office and production

SOFTWARE CONFIGURATION

Set-up and configuration of business software deployed at the client’s premises

DESIGN STANDARDS & CERTIFICATION

Liaising with organisations to certify our products according to the markets : DTA, CSTB, etc.

RESPONSIBLE,

100% French production

Total control of the production chain

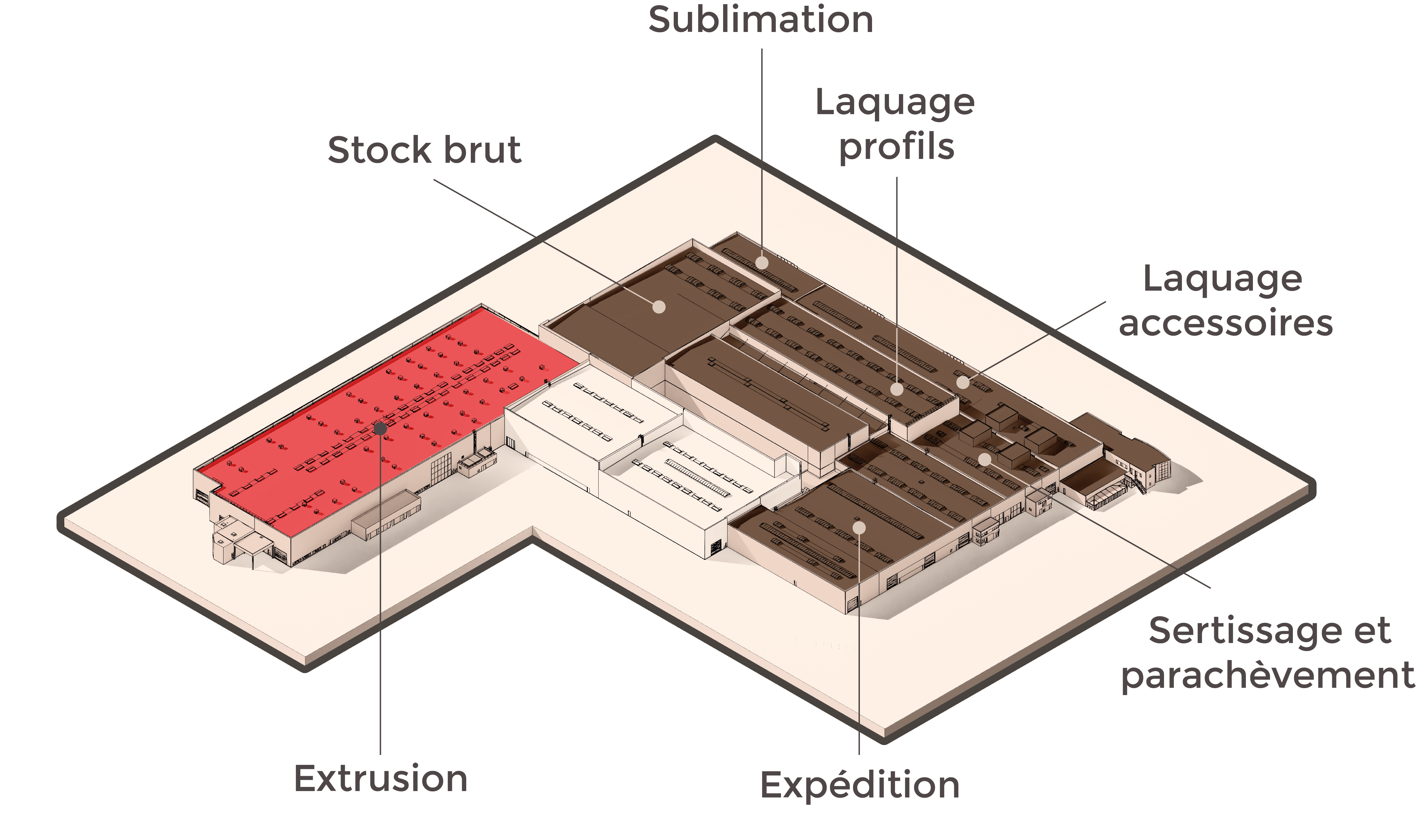

Sepalumic has integrated the entire production process into its 41,000 m2 site in Genlis (21) : lacquering (profiles, accessories and sublimation), crimping and finishing; and since 2023, an aluminium profile extrusion area. This covers 8000 m2 and boasts hybrid extrusion-press technology never before seen in France to better meet customers’ needs while reducing energy consumption by 30% (compared to the presses usually used).

A few key figures

- Painting capacity : 11,000 m² of profiles a day + 4,000 accessory units a day

-

Crimping capacity : 20,000 ml a day

- Area : 41,000 m²

RELIABLE AND SUSTAINABLE PRODUCTION:

Thanks to the integration of the extrusion area, Sepalumic now handles all the production stages of its aluminium profiles, thus providing an optimal quality of service for its customers :

- Better quality control

- Greater flexibility and speed in dealing with consumption increases or major construction projects

COMMITMENT TO CSR ON A DAILY BASIS

Our production and finishing facilities are equipped with the latest low-energy-production and management technologies, supplied with low-carbon aluminium. Closer to our customers than ever due to our logistical proximity, with our products and services we support them in their environmental initiatives and those of their architectural partners.

Our ambition enables us to make a humble contribution to sustainable construction!

EXTRUSION, FOR “GREEN”, LOCAL PRODUCTION

By relocating this area of production to France, Sepalumic is considerably reducing its carbon footprint. Less transport and less protective packaging waste, not to mention the advantage of 100% French production.

- Production from certified low-carbon aluminium

- A press using hybrid technology – one of a kind in France

-

Facilities powered by a solar farm Carbon-neutral solar farm

1 MWp of energy generated, i.e. 30% of the site’s total consumption

OUR CERTIFED ALU+C- SUPPLIERS

Created by the professional bodies SNFA and GFA to meet the expectations of environmental regulation RE 2020, the Alu+C- approach aims to certify players who offer aluminium products with a controlled carbon footprint thanks to defined criteria, both in terms of supply and the extrusion process.

This approach certifies that 30% of the aluminium supplied by Sepalumic is recycled and produced in Europe, and that the transformation of billets by extrusion into profiles respects a carbon quantity safeguard mechanism.

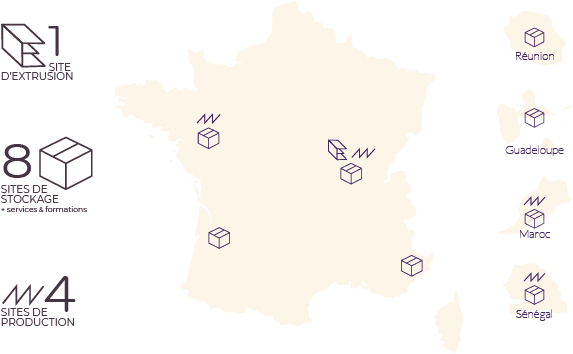

LOCAL LOGISTICS DEPOTS,

Closer to your workshops with our regional and international platforms and support services

Our industrial and logistical choices, made long ago, allow us to proudly display our full integration on French soil and gradual integration into overseas, European and African territories. Thanks to our 4 depots in France and our 4 depots outside mainland France, we provide our customers with a unique local service that allows us to react quickly to our customers’ requests. Flexibility, speed of service, and reduced transport: logistical proximity has always been our strength.

Committed employees who are proud to serve you

At Sepalumic, trusting, human relationships with our clients are paramount. We visit you regularly and listen to what you have to say because your opinions and feedback are invaluable to us.

Our 400 employees are committed to meeting your expectations on a daily basis to ensure maximum product and service quality.

-

Sales and technical staff on the ground to support you on a daily basis

-

Dedicated contacts to listen to you :

-

Customer service : sales management and after-sales

-

Support teams who work daily to ensure your satisfaction

-

Logistics coordinators, design offices, marketing and procurement to name just a few.